- Blog

How supply chains are re-defining resilience through smarter network design

A recap of the Roland Berger × Infios webinar on building...

Explore our findings on the role of digitization and process automation in supply chain success—where strategy meets the right software.

Supply chain digitization – also known as digital transformation, Supply Chain 4.0 or Logistics 4.0 – has become a necessity for businesses to survive in an environment of ever-increasing complexity. With shorter delivery times, SKU proliferation (more products), labor shortages and unexpected disruptions, supply chains are under pressure to be smarter, more productive, more efficient and adaptable.

The key to driving digitization is process automation using technology to improve supply chain workflows and ideally removing manual, paper-based processes. This in turn increases productivity, resilience, accuracy and transparency.

The digitized supply chain ecosystem is based on a connected set of digital technologies spanning supply chain software solutions such as supply chain planning, warehouse management systems (WMS), order management systems (OMS), transportation management systems (TMS), cloud platforms, the Internet of Things (IoT) and fixed and flexible warehouse automation technologies such as autonomous mobile robots (AMRs). Technology such as voice solutions can also remove manual and paper-based processes, contributing to an automated and digitized supply chain.

Rather than working in silos, supply and demand actions can be triggered at different points, traveling immediately through the network. This improves visibility and can help mitigate disruption effects such as increased consumer demand, missing product components or unplanned events. This way, supply chains become more agile and resilient.

Supply chain professionals have recognized the need for this. In the Gartner Future of Supply Chain Survey 2020, respondents rated “collaboration with customers and suppliers” at 82 percent the top reason for investment by supply chain managers.

According to a study by HBR Analytic Services, only 8 percent of companies have achieved the digital maturity required to achieve resilience and mitigate supply chain disruptions.

Digitized supply chains also capture data across the operation and use it to their advantage. Technology such as artificial intelligence (AI) and machine learning (ML) make use of it and create new insights to further increase efficiency.

In 2022, Infios launched a research project aiming to understand the underlying factors that drive supply chain complexity. The research project resulted in the identification of six operational areas:

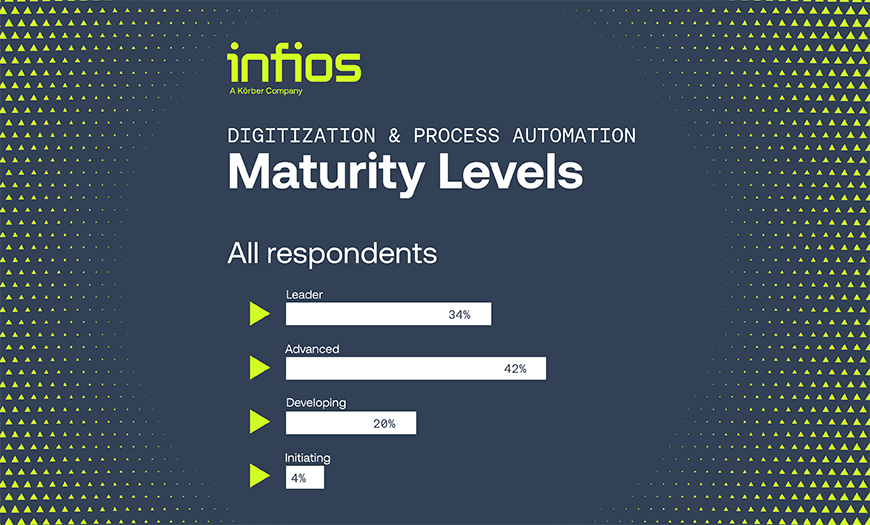

In response to these rising complexities, Infios then commissioned its first ever Supply Chain Benchmarking survey. The research was designed to assess current supply chain best practices and establish benchmarks. The results, based on a representative survey among more than 200 companies, shed unparalleled insight into the industry and best practices to improve supply chain operation and performance. Participants were scored and categorized into four maturity levels: leader, advanced, developing and initiating.

Our benchmarking survey found that the maturity levels for the complexity factor Digitization and Process Automation were as follows: Leaders, at 34 percent, are the second largest group for this complexity factor, followed by 40 percent of respondents that were classed as advanced while 20 percent ranked as developing and 4 percent as initiating.

Today’s supply chain leaders clearly understand the need for digitization and process automation. 84 percent of the companies we surveyed said that digitization plays a key role in their business strategy or is a high priority. That is why a third of the companies are in the leader category.

What factors distinguish a leader when it comes to digitization? Two of the most important are:

Interestingly, while organizations in all regions saw the importance of digitization and process automation, there are regional differences when it comes to implementation. While 48 percent of North American organizations qualify as leaders, only 21 percent of European businesses do.

Essential to Digitization and Process Automation is an underlying strategy. This considers the business as a whole and identifying suitable technologies to achieve the goal. However, while supply chain technology use is important, so is their integration and the capability to communicate. Non-integrated systems can in fact make achieving goals more difficult.

Below are some of the technologies that have been created to streamline supply chain operations.

Warehouse management systems (WMS), warehouse control systems (WCS), transportation management systems (TMS), yard management systems (YMS) and order management systems (OMS) are the foundation for digitizing and automating key processes in and outside of the warehouse.

On a hardware level, two key technologies stand out – the use of Voice and autonomous mobile robots.

Voice-directed work makes use of headsets that feed instructions directly to warehouse associates who confirm a task has been completed through the microphone. This streamlines operations, allows workers to keep their hands and eyes free compared to looking at picking lists. As a result, speed, accuracy and worker safety improves. This can eliminate paper-based processes.

AMRs work in collaboration with warehouse associates. They perform repetitive, difficult and time-consuming tasks, such as lifting and transporting pallets or single items. This way, workers can concentrate on value-added tasks. AMRs reduce transportation tasks and product handling, as well as task planning and implementation, improving productivity and efficiency.

Businesses that stay at the top of their game continue to innovate with the rising complexities of the supply chain. In other words, leaders see digitization and process automation as a core skill, while other supply chain operators see it as something that can be outsourced.

Want to learn more on what current supply chain Digitization and Process Automation leaders are doing? Download the full Benchmarking report for more details on the survey results.