- Brochure

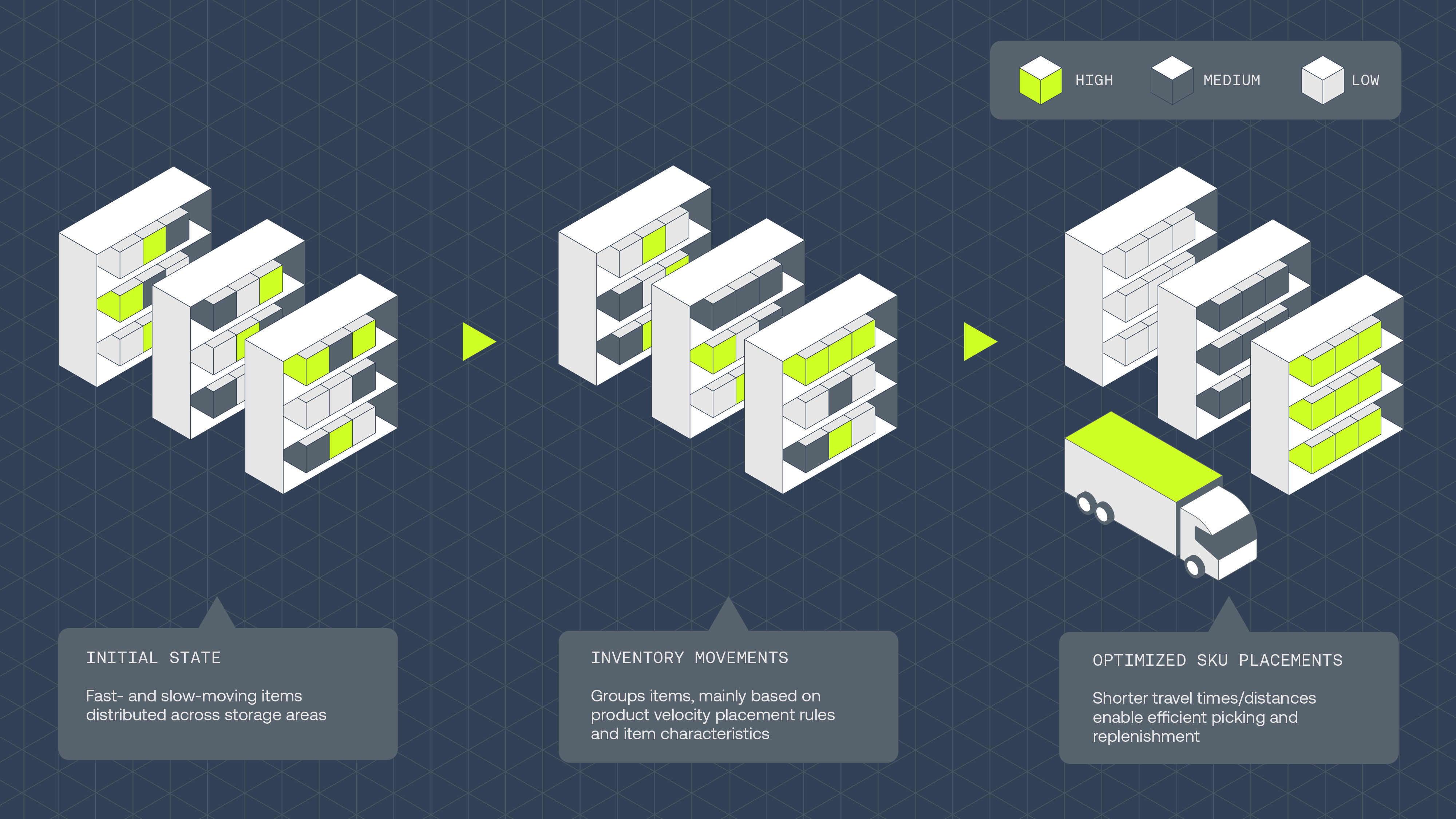

Our Slotting Solution optimizes inventory placements in warehouse storage areas to increase the efficiency of order picking and replenishment processes. Operational benefits include improved staff productivity, higher order throughput and more efficient use of limited storage space.

TALK TO AN EXPERT

Our Slotting Solution can help warehouse managers address these issues. It applies data science techniques and advanced analytics to optimize inventory placements based on product velocity, slot constraints and item characteristics. This significantly shortens the times required for order picking, thereby increasing the rate of on-time shipments, while the system-driven, accurate slotting helps reduce picking errors.

It also reduces replenishment efforts and helps to right-size storage slots, to enable more efficient use of limited storage space. Our solution also supports different slotting strategies and allows customers to select the best option for their needs.

Product movements required for re-slotting of inventory items are fed back into the Warehouse Management System (WMS) to enable integrated task planning.

A Slotting Solution is a software tool used in warehouse management to optimize the placement of inventory within the warehouse. It analyzes various factors such as SKU velocity, dimensions and storage requirements to determine the most efficient storage locations for each item.

A Slotting Solution helps maximize warehouse efficiency by organizing inventory in a way that minimizes travel time, reduces picking errors and increases throughput. By optimizing storage locations based on factors like demand patterns and SKU characteristics, slotting solutions improve overall warehouse productivity and accuracy.

Slotting Solutions consider various factors, including SKU velocity (how fast items sell), dimensions, weight, storage requirements (e.g., temperature or special handling) and picking frequency. By analyzing these factors, the solution determines the optimal storage locations for each item to minimize travel time and maximize efficiency.

Most Slotting Solutions are designed to seamlessly integrate with existing Warehouse Management platforms. They can exchange data with the WMS via APIs to access information about SKU attributes and storage locations and picking history. This integration ensures that slotting decisions are based on current data.

Yes, Slotting Solutions are designed to be dynamic and adaptable. They can be adapted to reflect promotional or seasonal SKUs, changing velocities and storage requirements. This flexibility allows warehouses to adjust slotting strategies based on evolving business needs.

Implementing a Slotting Solution can have a significant impact on your bottom line by improving warehouse efficiency and labor productivity and reducing late shipments and inventory damage. By optimizing inventory placement and streamlining picking processes, slotting solutions help warehouses operate more efficiently, leading to cost savings and increased profitability.

Slotting Solutions are best suited for medium to enterprise warehouses, with larger inventories. As inventories expand in size and complexity, the advantages of automated, efficient slotting become more pronounced.