- Blog

The great unraveling: ERP vs Order Management Systems

Struggling to choose between ERP and Order Management Sys...

Supply chains are complex. That complexity takes many forms as a product goes from ordered to fulfilled, because too many software, processes and operations come into place to get the order to its buyer.

A Warehouse Management System (WMS) is one of those central players in an order’s journey. For the uninitiated, a WMS is software that manages and executes operations of a warehouse, distribution, or fulfillment center. Meaning that a WMS can direct things like receiving and put away, or order picking and replenishment, or task management and wave planning, or labor and yard management, or so on.

On the other hand there is also an Order Management System (OMS). An OMS is an end-to-end system that aggregates inventory to be displayed across sales channels (eCommerce, mobile, physical) pre-purchase and centralizes operations with inventory visibility, order orchestration and customer communication across systems. Ultimately, an OMS becomes your single version of the truth; a system that owns your end-to-end customer, supplier and supply chain processes, allowing you to fulfill your brand promise anywhere your customer expects commerce.

Customer expectations are higher than ever before and have created increased complexities for businesses to manage. The pandemic may be in the rearview, but the learned behaviors have persisted. Consumers are as likely to place 10 orders of one item each as they are one order of 10 items. This habit has been encouraged by front-end systems that reduce the pain of ordering, but can cost an operation time, energy and money. And omni-channel fulfillment strategies that have increased the ease and speed of fulfillment like Buy Online Pick-up In Store and non-penalized return policies compound complexities (and costs) for an operation.

There is no going back; The best that can be hoped for is to leverage these models to increase customer loyalty, amplify the opportunity to increase revenue, or maybe capture back some of the costs. To accomplish any of these, an organization needs to evaluate their current state.

Fulfillment operations have been relying on WMS as the primary tool since 1972. The ensuing 50 years saw massive growth in commerce and transactions, and it took another 23 years for OMSs to enter the market. During that time, other systems like Enterprise Resource Planning (ERP) and Distributed Order Management (DOM) systems filled the need gap, but none address what the OMS does.

With many companies still running legacy systems and/or utilizing ERP for WMS capabilities, they are forgetting how today’s challenges are different than they were in 1972. Labor execution and utilization is different, the existence and changes to physical and digital automation; how that automation integrates with other systems; customization of software; basic or advanced capabilities, etc. And more importantly, commerce has completely evolved to create larger, globally distributed supply chain networks.

Commerce is linked to the supply chain and it is important to remember that eCommerce is just one channel. In its truest form, “electronic commerce” has been occurring for decades via Electronic Data Interface (EDI). And while that channel has dominated the focus of many companies, there is a need to think about entire supply chain (and its many channels) system as it provides the execution roadmap of the customer expectation. Just as commerce has grown, supply chains are getting more complex, more distributed and, in many cases, global.

The recurring problem is the increase in complexity, as mentioned before; especially the inference being order volume and speed. The failure mode of this complexity is in how systems that claim to have OMS capabilities are missing the reality. For a vast majority of claimants, Order Management is a very linear process. “I get an order and I direct it to one of two warehouses based on proximity, with the other warehouse acting as the back-up.” The reality is: we do not live in a linear world. We live in a logarithmic world. For every node, an exponential increase of needs. And thus, an open question: Are your current metrics aligned with business you aspire to have? Or are they designed for your historic business (built on older system limitations)?

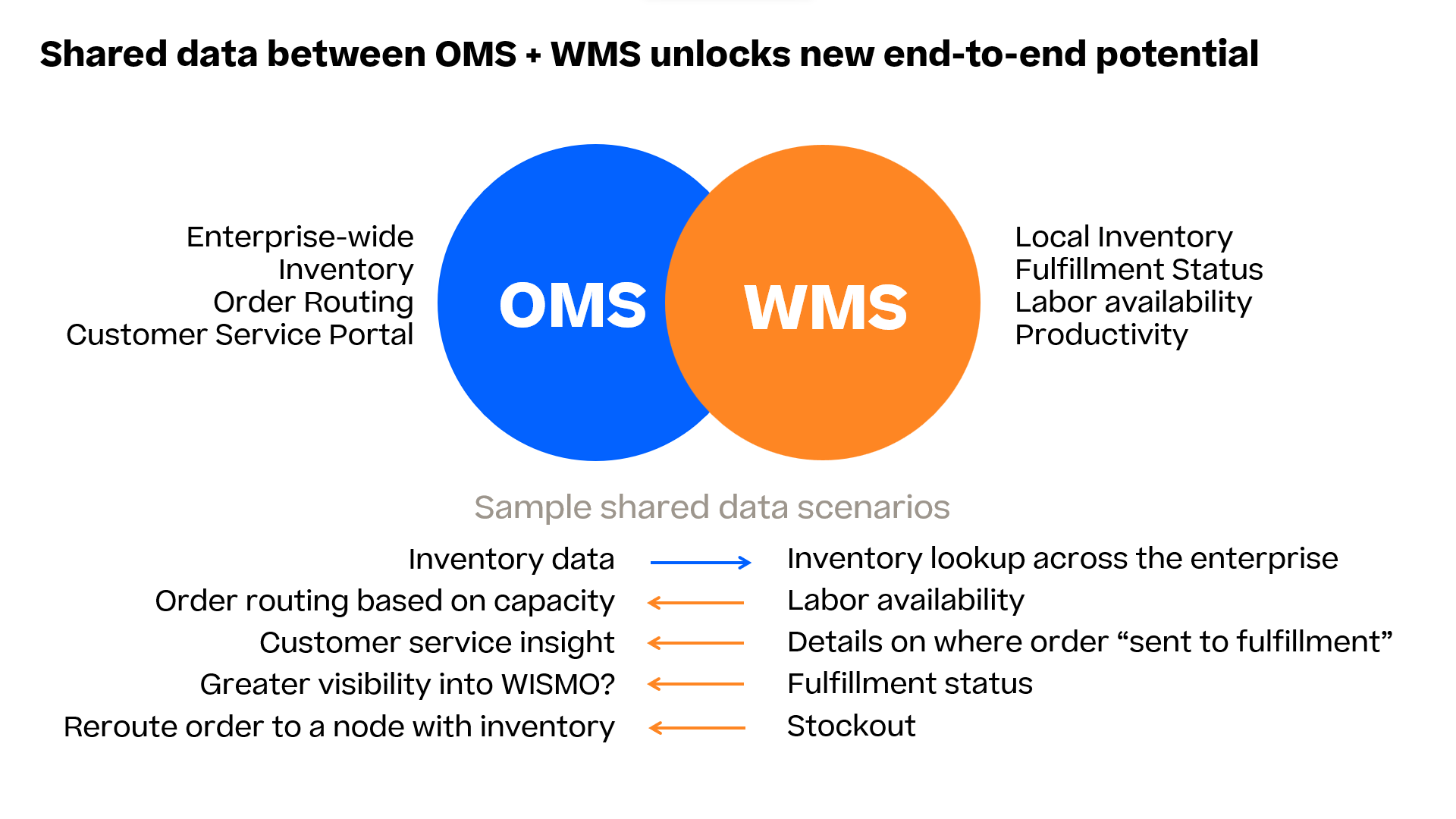

The combination of an OMS and WMS can be disruptive for an organization. By getting the two systems to work in perfect synch, supply chain excellence is achieved and business strategies for growth become a reality.

There are 4 Pillars of OMS and let’s look at the way that each interacts with a WMS.

By the time since the Warehouse Management SystemsWMS was introduced, software filled gaps that it was not designed to solve. ERP has been a round peg in a square hole; it fits with a little force and maneuvering, but there are inherent gaps that cannot be filled by a software that was not purpose built for the problem. An OMS is purpose built to unlock new end-to-end potential for an operation.

The end point is an improved customer experience from an organization that can:

And those are just the operational implications. Customers of Infios OMS and WMS have made strides in their supply chain by leveraging business logic to gain new levels of flexibility such as the ability to allocate orders against “in transit” future inventory. This can lead to a 70% reduction in backorders, which lead to decreased delivery costs, and most important improved margin across the entirety of the business.