- Blog

How supply chains are re-defining resilience through smarter network design

A recap of the Roland Berger × Infios webinar on building...

Navigate fresh logistics easily by learning insights into the produce peak season and how to leverage our technology for greater efficiency.

Efficient, cost-effective fresh logistics processes improve the accessibility and affordability of healthy, high-quality products, especially during the produce peak season.

Although we’ve been told to eat vegetables all our lives, only a small percentage of the U.S. consumes the recommended amounts of fruits and vegetables. The tide is turning, however. Younger generations are more concerned about the foods they eat and how they are sourced.

Price disparity between healthy options and low-cost “junk foods” persists. Yet, consumer awareness and targeted produce programs are beginning to break down barriers.

As the demand for fresh produce increases, so does the complexity of managing peak seasons in fresh logistics.

This article explores fresh logistics. We emphasize the need for efficiency, technology adoption, and waste reduction to enhance the availability of nutritious produce. Further, we will explore strategies for navigating produce peak seasons and demonstrate how Infios' optimization tools empower logistics operations to thrive.

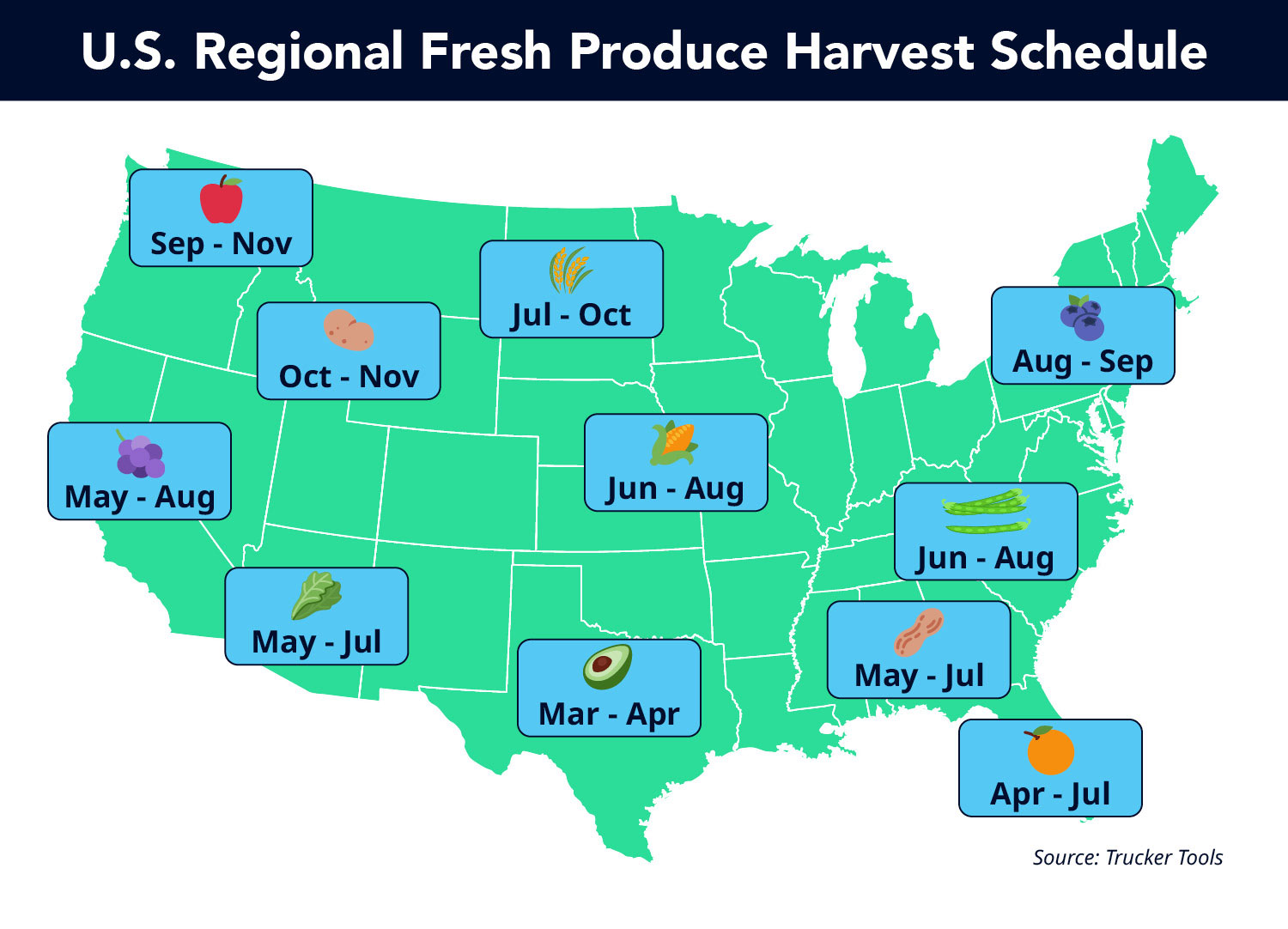

While we can get most fruits and vegetables year-round through a balance of imports and domestic sources, different environmental growth requirements drive varying produce peak seasons throughout the year.

Each region’s peak season, from the Pacific Northwest’s blueberries to the South’s peaches, commands a unique logistics strategy. Knowing the timing of different produce seasons and how to prepare helps you drive efficiencies in your fresh logistics operation. For example, transitioning from produce imports to focusing on domestic produce during warmer weather requires a significant shift.

California accounts for the lion’s share of our country’s fruit and vegetable production. That said, the rest of the country produces significant volumes throughout the year. The United States Department of Agriculture (USDA) provides a comprehensive seasonal produce guide.

Here is a condensed version:

Spring: asparagus, strawberries, lettuce, carrots, garlic.

Summer: tomatoes, corn, watermelon, berries (blueberries, raspberries, blackberries), peaches.

Fall: apples, pumpkin, sweet potatoes, cranberries, brussels sprouts.

Winter: citrus fruits (oranges, lemons, grapefruits), root vegetables (beets, carrots, parsnips), kale, pears, winter squash.

Seasonal produce surges create excitement for harvest festivals and family-favorite recipes. This season also challenges fresh logistics operations in various ways, from securing transportation capacity to managing warehouse space effectively. Planning and establishing robust and collaborative relationships with suppliers ensures a smooth transition into the busy produce logistics season.

Planning ahead helps secure capacity for your peak-season harvest. Mitch Mazzaro, director of retail and food service at Arrive Logistics, told FreightWaves that shippers should start securing capacity well before the peak of produce season. Focus early discussions about capacity and truck placements in regions such as Florida and south Georgia, which kick off the season on the East Coast, and in Northern California areas like Salinas on the West Coast.

Preparation helps mitigate disruptions and maximize efficiency. Relying on past produce peak seasons as a predictor of the future is a good baseline. From there, incorporating insights about the freight market, product yields, and other factors helps shape an effective fresh logistics strategy.

Many shippers leverage reports such as the USDA’s Specialty Crops National Truck Rate Report to gain insights into truck capacity. The Cass Freight Index offers a snapshot of freight volumes and expenditures.

Here are essential tips for managing fresh logistics:

Doing your homework goes a long way toward preparing for a successful produce peak season. Likewise, leveraging technology to improve planning and execution helps you navigate the challenges of produce peak seasons.

Automation tools such as transportation management systems (TMS) streamline processes and improve efficiency by providing real-time tracking, intelligent routing and scheduling, and data analytics.

By harnessing Infios' TMS technology, you can optimize logistics planning, mitigate disruptions, and ensure smooth operations. Our platform supports fresh logistics by:

Our solutions help produce shippers navigate the current challenges and set the stage for a more resilient fresh logistics supply chain.

Navigating fresh logistics requires a strategic approach grounded in a thorough understanding of produce seasonality. Leveraging technology for fresh logistics proves to be a game changer and sets an optimistic tone for the future of the produce supply chain.

Infios stands at the forefront of this journey by enabling businesses to transform their fresh logistics operations. As we embrace the blooming 2024 produce season, Infios invites you to experience the full potential of our platform. Request a demo today and learn how we can help you optimize your fresh logistics for the coming seasons.