- Blog

How supply chains are re-defining resilience through smarter network design

A recap of the Roland Berger × Infios webinar on building...

Demand peaks are inevitable in the consumer goods industry. Companies that can adapt quickly to these fluctuations gain a significant competitive edge.

Demand peaks are a common yet challenging reality for businesses in the consumer goods sector.

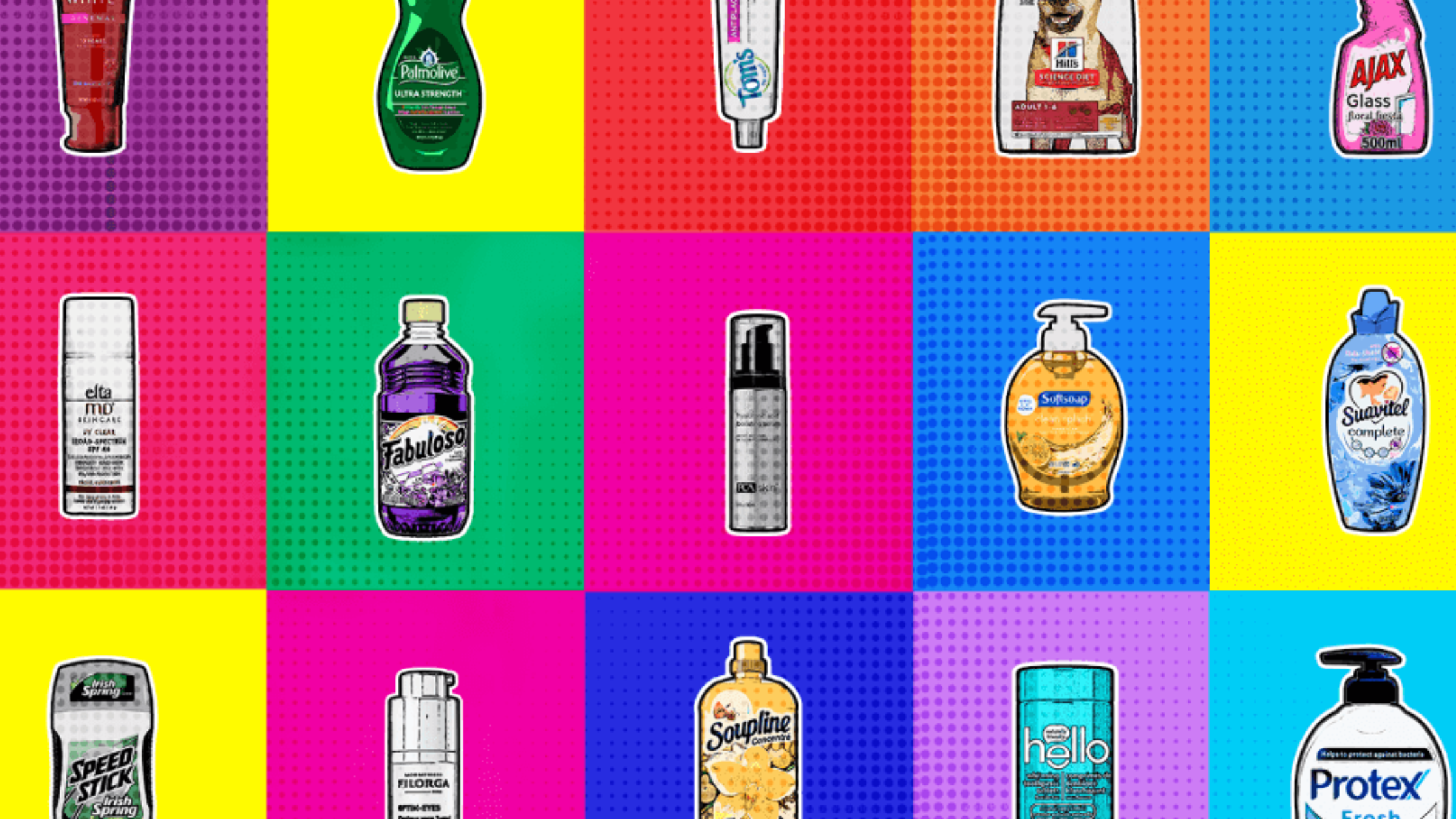

For Colgate-Palmolive—a global leader in oral care, personal hygiene and home products—handling these spikes effectively is crucial to meeting customer expectations and maintaining operational efficiency.

With a supply chain spanning multiple continents and serving millions of consumers daily, Colgate-Palmolive’s approach to managing inventory flexibility during periods of high demand offers valuable insights.

For consumer goods companies, demand spikes can arise from a variety of sources:

These spikes put immense pressure on supply chains. Overstocking ties up valuable capital, while understocking risks losing revenue and damaging customer relationships.

A study by McKinsey & Company found that nearly 80% of companies experience supply chain disruptions annually, many of which stem from demand fluctuations.

Colgate-Palmolive’s ability to navigate these challenges is a testament to its proactive and adaptive approach to inventory management.

At the heart of Colgate-Palmolive’s success is its reliance on robust demand forecasting. By leveraging historical sales data, market trends and real-time analytics, the company accurately predicts future demand patterns.

For instance, during the annual back-to-school season, demand for oral care products such as toothpaste and toothbrushes sees a significant uptick. Colgate-Palmolive’s predictive models enable the company to prepare ahead of time, ensuring shelves are stocked while minimizing waste.

The company also employs dynamic demand monitoring during active campaigns. This allows for mid-cycle adjustments when sales volumes exceed or fall short of initial projections.

Flexibility in manufacturing is another critical component of Colgate-Palmolive’s strategy. The company’s production lines are designed for agility, enabling rapid shifts between product categories.

For example, when demand spikes for hand soaps and sanitizers, the company can prioritize these products without disrupting production schedules for other goods.

On the logistics side, Colgate-Palmolive uses strategically located regional warehouses to ensure fast delivery to high-demand areas. This decentralized model minimizes transportation delays and helps the company respond swiftly to changing consumer needs.

Colgate-Palmolive understands the importance of strong supplier relationships in maintaining inventory flexibility

By engaging in collaborative planning with key suppliers, the company ensures a steady supply of raw materials during demand peaks.

This collaboration includes shared forecasting, advanced notice of production changes, and contingency planning for potential disruptions. For example, during the pandemic, this approach helped Colgate-Palmolive secure critical inputs like alcohol and glycerin for hygiene products.

Technology plays a transformative role in Colgate-Palmolive’s inventory management strategy.

Digital twins - virtual replicas of supply chain operations—allow the company to simulate demand scenarios, identify bottlenecks, and test solutions in a risk-free environment.

Additionally, AI-driven analytics provide actionable insights for optimizing inventory levels, reducing waste, and enhancing service quality. These tools help Colgate-Palmolive maintain a proactive stance, reducing the impact of unforeseen demand fluctuations.

Colgate-Palmolive’s strategies offer several takeaways for businesses seeking to enhance their inventory flexibility:

While Colgate-Palmolive’s approach is impressive, not every business has the same level of resources or expertise. This is where advanced technologies like Infios’s inventory management solutions can help.

Inventory optimization

Infios’s inventory and slotting solutions streamline stock allocation across distribution centers, ensuring products are available where and when they’re needed. This reduces carrying costs while improving customer service levels.

End-to-End visibility

With Infios’s integrated systems, businesses gain full visibility into their supply chain operations. Real-time data dashboards provide actionable insights, helping companies adapt quickly to changing demand patterns.

Scenario planning

Infios’s simulation tool allows businesses to test various demand scenarios and develop contingency plans. This reduces the risks associated with unexpected demand surges, ensuring supply chain resilience.

“Without Infios’s warehouse solution, we wouldn’t have survived or been as successful during the COVID-19 pandemic.”

Nassau Provisions specializes in the distribution of specialty and general groceries. The company serves supermarkets, restaurants, convenience stores and delicatessens with a vast portfolio of products that rely upon a variety of temperature zones.

The company’s peak season encompasses the holiday of Passover, where the organization typically processes up to 15,000 cases of product per day.

Nassau Provisions biggest challenge was the complexity of products around the holiday period, when many vendors create limited-time Passover versions of products that already exist in the warehouse.

As the company began to grow it soon realized that processing complex products using an outdated manual system during peak season was unreliable and a risk to the company’s success.

Partnering with Infios using the Warehouse Management System and Voice Solutions work, the company was able to mitigate the challenges of elevated demand during a pandemic. The results included:

Demand peaks are inevitable in the consumer goods industry. Companies that can adapt quickly to these fluctuations gain a significant competitive edge. Colgate-Palmolive’s strategies demonstrate the value of foresight, agility and collaboration in navigating these challenges.

For businesses looking to emulate this success, solutions like those from Infios offer practical tools for achieving inventory flexibility. From demand forecasting to end-to-end visibility, these technologies provide the foundation for a resilient and responsive supply chain.

Colgate-Palmolive’s ability to meet demand spikes without compromising service levels is a testament to its operational excellence. By adopting similar strategies and leveraging advanced tools, businesses can position themselves for sustained success in a dynamic market.

Image copyrights:

Image 1: https://www.colgatepalmolive.com/content/dam/cp-sites/corporate/corporate-2021/carousel-components/image-banner/colgate-palmolive-brands-banner.png